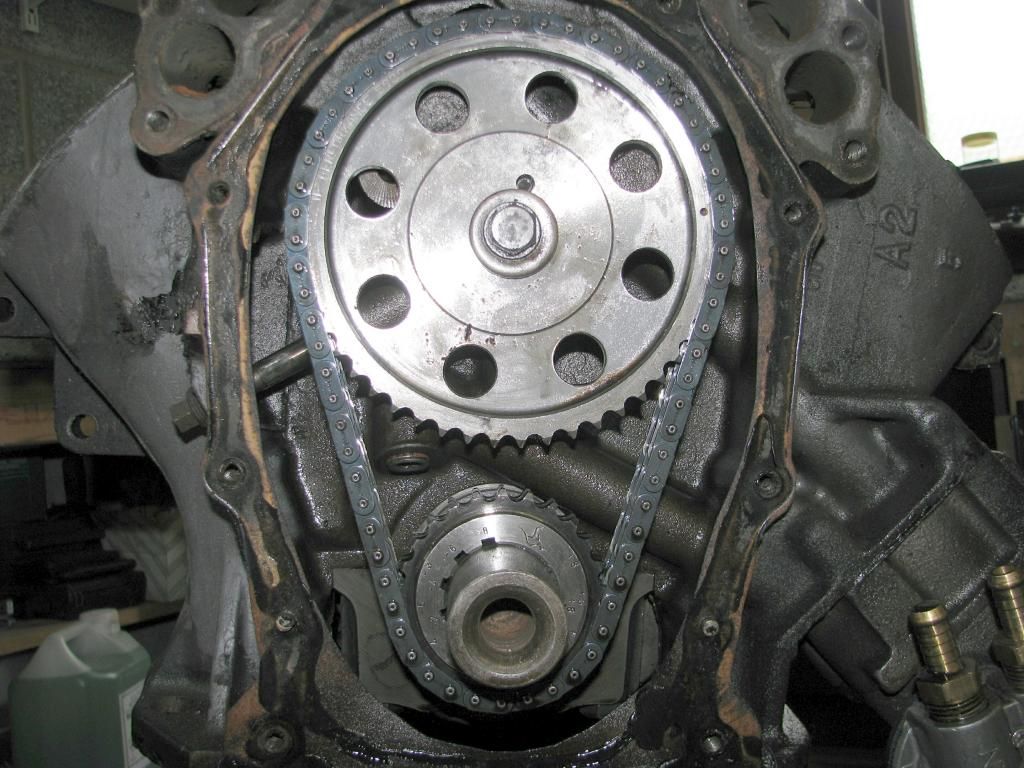

The timing gear is obviously of the adjustable type and the clowns who first rebuilt this engine did not know how to fit it either, resulting in piston - valve contact. Not serious for the pistons but I still had to replace some of the inlet valves.

So I need advice on proper position for the cam gear on replacement.

The crank gear has not been removed and the key is in the 0° position....

....... on the inner scale.

My question is: to which point (presumably on the outer scale?) should I line up the dot on the cam gear?

Logic would say to the 0° position again ............... but is that right?

Advice appreciated, thanks. (I've tried to find instructions on the Net - to no avail).