1/4 turn anti clockwise to clip the horn push back in which fits with the orientation of the hooky bits on that plate

kinda suggests that plate goes in the boss of the wheel with the collar on top?

or maybe that collar just insulates the top of the fat spring you stuck down the hole and presses against the back of the wheel.

that makes more sense

1) bit more of a cab over design than a car

2) no collapsible tube

3) allows wheel to ride on the splines so if you hit steering box hard on something like a curb stone the wheel won't jump as hard and smash your fingers

so

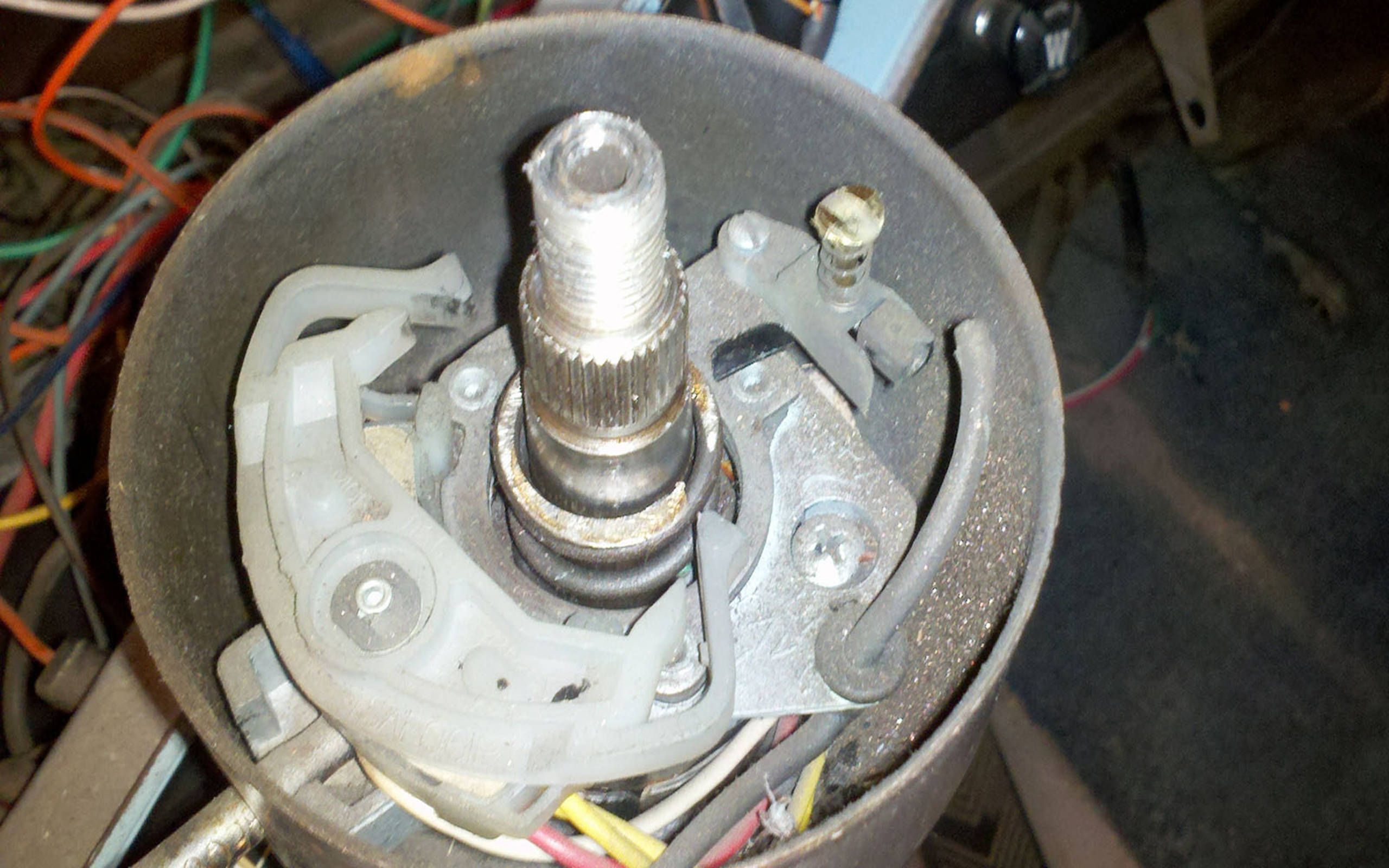

fat coil spring

collar/insulator Chrylser wouldn't have a spring steel spring sitting against a pot metal wheel even if the spline section is different, unlike metals prompt corrosion...! but its most likely just to stop it rattling

wheel

then the rest of the gubbins is horn push

you'll need to experiment as the NUT needs to fit on the shaft and of course i forgot about that

but all just a guess

i think you need a workshop manual...

Dave